Cut off Carriage Cutters (C.O.C Cutters)

In case of on-line Tube Cutting, one of the most recognised methods is by using three small round cutters which press the tube from three points while the cutting head is rotating around the tube. Cutters keep rotating and come closer to part off the tube. This method is used upto 75 mt./min. of Mill Speed. Tubes upto 76.2 dia can be cut. The cut is smooth, but cut edges get bent towards inside.

Recommended C.O.C. Cutter thickness for various wall thickness tubes (Refer Attachemnt)

Generally C.O.C. Cutters have two bevels at the cutting edge. Second bevel acts as relief to cutting edge.

Performance of C.O.C. Cutters depends upon alignment of three cutters in one plane. Hence thickness of C.O.C. Cutters should be maintained within close tolerance.

Raw Material For C.O.C CuttersFor O.D. series tubes, generally wall thickness is lesser and hence high speed steel gives good results. But in case of N.B. series pipes it is recommended to use hot die steel, as some shock resistance property is desired. Normally included cutting angle is 50 degree and relief angle is 16 degree.

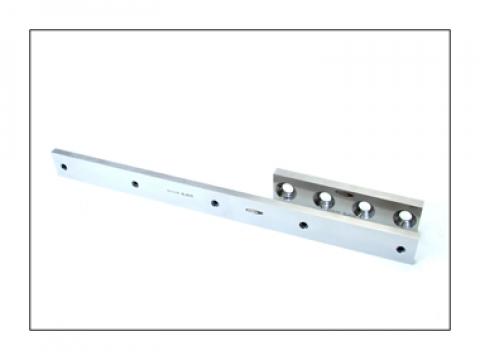

Cutter arrangement for CUT OFF CARRIAGE (Refer Attachment for drawings) TO PREVIEW THE COMPLETE ARTICLE DOWNLOAD FROM THE ATTACHMENT SECTIONEmail To a Friend

Print Version

Plain Text

Most Recent

Most Recent