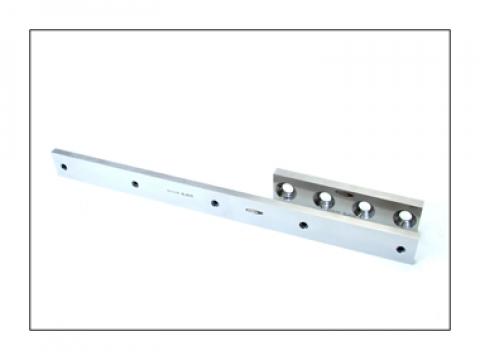

Slitter Tooling - Over Arm Seperators

In any Slitting Line, there is an uncoiler, slitter head and recoiler. After Slitting, many strands come out of the slitter head. These strands are to be coiled separately,

neatly so that their edges are protected. Packing and despatch to actual user becomes easy and productive; for which OVER ARM SEPARATOR DISCS (OASD) are used. These Over Arm Separators are mounted on a separate shaft which is lifted hydraulically as the narrow width coils keep winding. Over Arm Separators separate the narrow coils.Because of separators, the total width of slitted coils is more compared to incoming wide width coil, which is called Fan Out.

If number of strands are more, fan out is more. Generally, the face of recoiler is kept off set by 1" from Slitter face so that fan out on both sides from centre is equal.

Over Arm Separator Disc is an important item of Slitting Line Tooling. Slitted coils will be nicely wrapped and packed without spoiling edges if Over Arm Separator Discs are of good quality.

Over Arm Separator Discs are subjected to heavy wear and impact. Hence Raw Material should be wear resistant and shock resistant.

If OASD breaks frequently then either strip is not aligned or hardness of OASD is more. If OASD wears out faster, then material and hardness of OASD should be reviewed.

RAW MATERIAL AND HARDNESS OF OVER ARM SEPARATOR DISCS -

Raw material for OASD should be tough and wear resistant and AISI-D2 is supposed to be most appropriate raw material for OASD.

RAW MATERIALS FOR OASD IN ORDER OF PREFERENCE ARE :

(Refer Attachments)GENERALLY RECOMMENDED TOLERANCES ARE -

(Refer Attachment) TO PREVIEW THE COMPLETE ARTICLE DOWNLOAD FROM THE ATTACHMENT SECTIONEmail To a Friend

Print Version

Plain Text

Most Recent

Most Recent