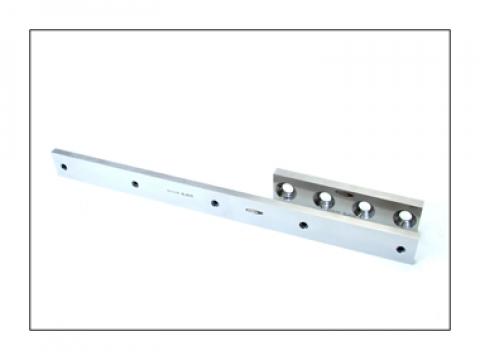

Slitting knife Clearance

SLITTING CLEARANCE: Proper knife clearance minimizes burr, increases knife's life by reducing wear and tear. Italso reduces stress on the machine and improves slit width tolerance.

While slitting, knives cut partially through the metal. The material then fractures, the rest of the way. The angle of the fracture is same, regardless of the metal being processed. The thickness and tensile strength of the metal determine knife clearance.

WHAT HAPPENS IN SLITTINGAs the metal strip enters the knives (step 1 in diagram), the strip penetrates the knives (step 2) until the forces exceed the ultimate tensile strength of the material and the strip separates (step 3). The penetration forms nick at strip edge and the separation is called the break. The depth of penetration is determined by the ultimate tensile

strength of the material and its relationship to the yield strength and the thickness of the strip.

For Diagrams Refer AttachmentWhen knife clearance is correct and the knives are in good condition, a good slit edge will be produced. The ideal slit edge will have:

- A shiny penetration zone (or nick)

- A smooth, matte grey separation zone (the break)

- A relatively straight demarcation line between the two zones

The most important factor in achieving an ideal slit edge is the horizontal clearance between a pair of slitter knives. The proper horizontal clearance depends primarily on the:

- Thickness of the material

- Tensile strength of the material

In general, as the gauge of the strip and/or its tensile strength increases, so should the horizontal clearance between the knife faces. Other important factors that must be taken into account when choosing the horizontal clearance are:

- A deeper than normal nick

- A smaller than usual break (REFER ATTACHMENT FOR DIAGRAMS)

- A burr on the bottom edge

Because more force than normal is required to separate the strip when knives are too tight, the knives tend to chip off. Unnecessary forces are imparted to the strip and to the slitter head itself.

1.2 KNIVES SET TOO FAR APART (Excess horizontal clearance) :When the knives are set too far apart, strip tears. The resulting edge may have:

- No noticeable nick

- A heavy roll over on the top of the strip (REFER ATTACHMENT FOR DIAGRAMS)

- A heavy burr on the bottom of the strip

It is easy to see the roll over and the burr on the slit edge. In effect, the slitter knives are acting as bending dies.

The quality of the slit edge and knife life will depend largely on the care with which setting between knives is made.

There is an optimum knife setting for every thickness and type of metal. When we speak of knife setting, we mean both horizontal clearance and vertical clearance. The clearance, vertical and horizontal, must be considered together because one affects the other.

TO PREVIEW THE COMPLETE ARTICLE DOWNLOAD FROM THE ATTACHMENT SECTIONEmail To a Friend

Print Version

Plain Text

Most Recent

Most Recent